Powder Coating Treatment of Aluminium Extrusion Heatsink

Aluminium extrusion heatsinks play a pivotal role in thermal management across a wide array of electronic and industrial applications. Their performance, longevity, and aesthetic appeal can be significantly enhanced through surface treatments. In this blog post, as a high quality custom aluminum heatsink manufacturer, Vibo will share powder coating treatment of aluminium extrusion heatsink for sale.

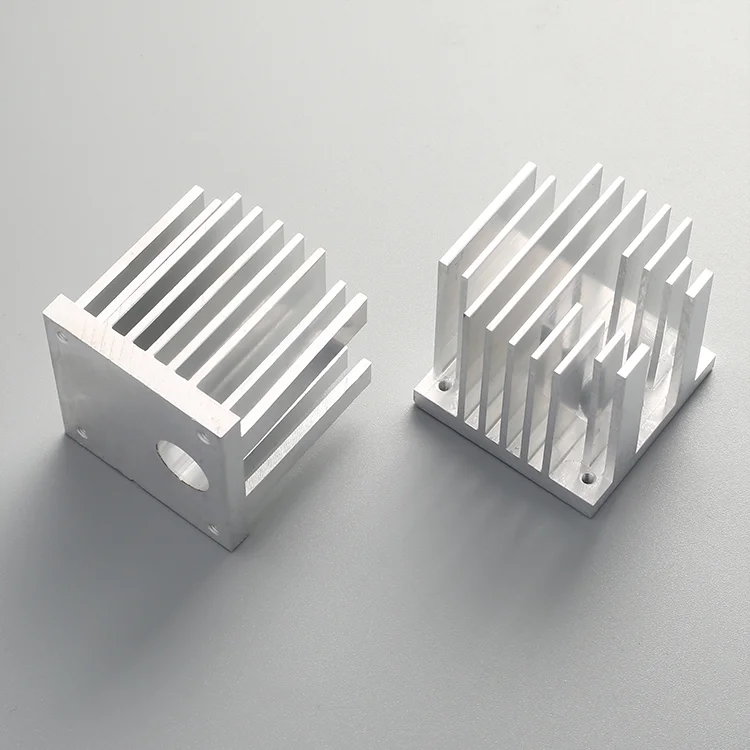

1. Understanding Aluminium Extrusion Heatsink for sale

Aluminium heatsinks are commonly manufactured through the extrusion process, where a billet of aluminium is heated and forced through a die of the desired cross-sectional profile. The resulting long sections can be cut, machined, and formed as required. Aluminium is the preferred material due to its high thermal conductivity (~205 W/m·K for 6063 alloy), lightweight, corrosion resistance, and ease of fabrication.

Extruded heatsinks are used extensively in power electronics, LED lighting, computer hardware, renewable energy systems, and more. Surface treatment becomes essential for protecting the heatsink in harsh environments, improving aesthetic quality, and sometimes enhancing thermal radiation. Powder coating serves this purpose effectively, albeit with certain trade-offs.

2. What is Powder Coating?

Powder coating is a type of dry finishing process in which a free-flowing, electrostatically charged powder is sprayed onto a metal surface. The coated part is then cured under heat, causing the powder to melt, flow, and form a uniform, hard finish.

Powder coatings are typically made from thermoplastic or thermoset polymers combined with pigments, leveling agents, flow modifiers, and other additives. Once cured, the resulting surface is robust, durable, and highly resistant to abrasion, corrosion, UV radiation, and chemicals.

3. Why Powder Coat Aluminium Heatsink?

There are several compelling reasons to powder coat aluminium extrusion heatsinks:

* Corrosion Protection: Aluminium naturally forms an oxide layer that offers basic protection. However, in marine, industrial, or polluted environments, this layer can degrade. Powder coating acts as a barrier against moisture, salts, acids, and pollutants.

* Aesthetics: Powder coating allows a wide variety of colors, finishes (matte, gloss, textured), and effects (metallic, speckled) to be applied, which is essential for visible or consumer-facing components.

* Electrical Insulation: In some applications, the coating can provide dielectric insulation to prevent short circuits.

* Surface Uniformity: Powder coatings can hide minor surface imperfections and machining marks better than anodizing or bare finishes.

However, it' s crucial to acknowledge the thermal performance impact of such coatings, which will be discussed later.

4. Aluminium Extrusion Heatsink Powder Coating Treatment

The powder coating process comprises several critical stages:

4.1. Pre-treatment

Pre-treatment is essential for ensuring strong adhesion between the coating and the aluminium substrate. Typical steps include:

* Degreasing: Removes oils, machining lubricants, and contaminants using alkaline or solvent-based cleaners.

* Etching: An acid or alkaline etch roughens the surface microscopically, increasing the surface area for bonding.

* Deionized Water Rinse: Ensures no residues are left on the surface.

* Chromate or Non-chromate Conversion Coating: Improves corrosion resistance and adhesion. Chromate treatments are more effective but raise environmental concerns.

4.2. Drying

The cleaned and pre-treated aluminium heatsinks must be thoroughly dried before applying the powder. Any residual moisture can lead to poor coating adhesion, outgassing, or pinholes.

4.3. Electrostatic Powder Application

Using a corona or tribo gun, powder particles are charged and sprayed onto the grounded aluminium heatsink. The electrostatic attraction causes the powder to adhere uniformly to the surface, even on fins and recessed areas.

Key parameters include:

* Voltage: Typically between 60–100 kV for electrostatic guns.

* Gun-to-part distance: Usually 15–25 cm, depending on geometry.

* Air pressure and flow rate: Optimized to prevent excessive overspray or uneven build-up.

4.4. Curing

After application, the coated heatsink is transferred to a curing oven, where it is heated to a temperature between 160–220°C for 10–30 minutes (depending on powder type and mass of the part). Thermosetting powders undergo cross-linking reactions that form a solid, stable network.

Common oven types include convection ovens (hot air), infrared ovens, and combination types.

5. Effects on Thermal Performance

While powder coating provides excellent mechanical and chemical benefits, its impact on thermal management must be carefully considered, especially for heatsinks.

5.1. Thermal Conductivity

Powder coating materials are generally poor thermal conductors, with thermal conductivities in the range of 0.2–0.4 W/m·K. This is several orders of magnitude lower than aluminium. Therefore, any coating adds thermal resistance to the path from the heatsink surface to the ambient environment.

5.2. Emissivity Enhancement

Interestingly, some powder coatings, especially those in black or matte finishes, increase the emissivity of the heatsink surface. Bare aluminium has a low emissivity (\~0.05), while black powder coatings can raise this to 0.85–0.95, improving radiative heat transfer, particularly important in natural convection or radiation-dominated cooling environments.

5.3. Trade-off Considerations

For high-power applications where conduction and convection dominate, thick powder coatings might impair performance. For low-to-moderate heat loads or systems relying on radiation, coatings can be beneficial. Engineers must evaluate these factors case by case.

6. Design and Application Considerations

To optimize the use of powder coating on aluminium extrusion heatsinks, consider the following:

* Coating Thickness: Typically between 60–100 microns. Thinner coatings may be specified for fine-fin heatsinks to minimize thermal resistance.

* Color Selection: Black coatings offer high emissivity, aiding heat dissipation via radiation. Light or metallic colors reflect more IR radiation and may hinder heat rejection.

* Masking: Threads, electrical contact areas, and tight tolerance features should be masked before coating to preserve dimensional and functional integrity.

* Geometry Challenges: Complex heatsink profiles with deep fins may suffer from “Faraday cage” effects, where powder does not easily reach into corners. Skilled applicators and multiple pass spraying can alleviate this.

* Outgassing Control: Aluminium castings or extrusions with porosity may outgas during curing, causing bubbles or pinholes. Proper pre-bake or outgassing cycles are recommended.

7. Alternatives and Comparisons

Powder coating is one of several surface treatments for aluminium heatsinks:

|

Treatment |

Benefits |

Limitations |

|

Anodizing |

Durable, thin, maintains thermal contact |

Limited color range, costlier |

|

Bare Aluminium |

Best thermal performance |

Poor corrosion resistance, low emissivity |

|

Painting |

Flexible, lower-cost coating |

Less durable, thinner films |

|

Electroless Nickel |

High conductivity, corrosion protection |

Expensive, may alter dimensions |

The choice depends on application-specific trade-offs involving cost, thermal performance, appearance, and environmental exposure.

8. Conclusion

Powder coating offers a robust, aesthetically pleasing, and protective surface finish for aluminium extrusion heatsinks. While it may introduce a slight thermal resistance due to its insulating nature, the improved emissivity and enhanced durability often outweigh the drawbacks, especially in non-critical thermal applications.

Engineers must carefully assess the thermal, mechanical, and aesthetic requirements of their systems before selecting powder coating. With proper design, application, and process control, powder-coated aluminium heatsinks can achieve excellent performance and longevity in a wide range of environments.

www.viboprecision.com

Vibo

Post Comment