Application Advantages Of Precision Air Compressor Gear

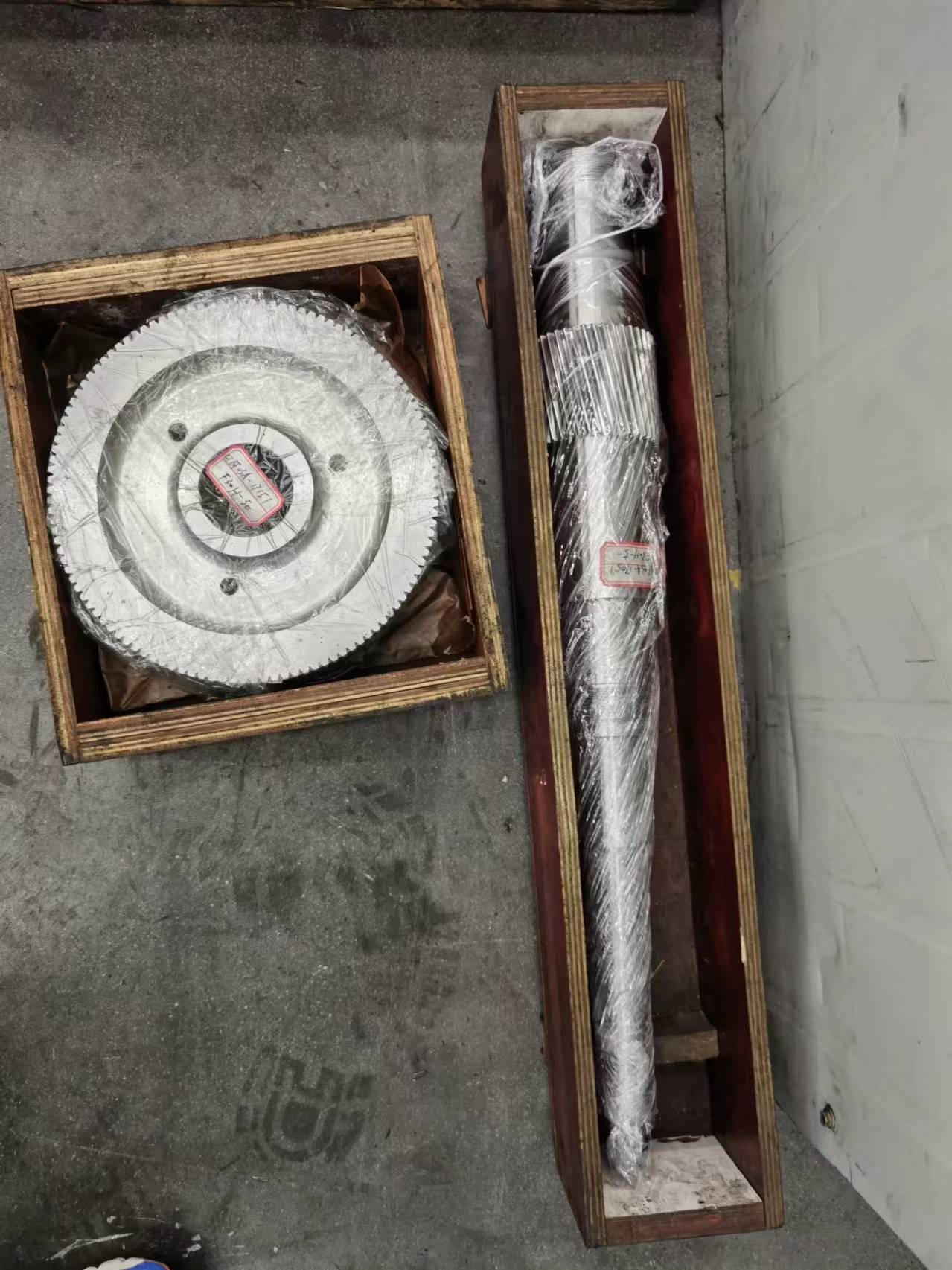

Compressor gears are critical mechanical components engineered to transfer motion and torque efficiently within air compressor systems. These gears are designed to function with high reliability and accuracy under continuous operation, offering substantial performance advantages across various industrial sectors. In this blog post, as a high performance industrial gear manufacturing factory, Longruifa will share the application advantages of precision air compressor gear for sale, which plays an important role in efficiency, durability and system integration.

Precision Air Compressor Gear Application Advantages

1. Enhanced Mechanical Efficiency

One of the foremost advantages of precision air compressor gears is their contribution to improved mechanical efficiency. These gears are manufactured with tight tolerances - often in the micron range - ensuring optimal meshing and minimal backlash. The result is smooth power transmission with reduced energy loss due to friction or misalignment.

* Helical and Spur Gears: Precision gears often feature helical teeth, which engage gradually and reduce shock loads. This design enables quieter operation and higher load capacity compared to standard spur gears.

* Precision Grinding: Advanced gear grinding processes yield surfaces with low roughness and high dimensional accuracy, reducing rolling resistance and heat generation within the gear train.

The increased efficiency translates to reduced power consumption, a key factor in cost savings over the operational lifespan of an air compressor.

2. Superior Load-Bearing Capacity

Air compressors - particularly rotary screw and scroll types - operate under high loads and pressures. Precision gears are engineered to handle these demands effectively through optimized material selection and geometry.

* Material Engineering: High-grade alloy steels, such as 20CrMnTi or 18CrNiMo7-6, are often used. These materials undergo case hardening (carburizing or nitriding) to increase surface hardness while retaining a tough core for impact resistance.

* Tooth Profile Optimization: Precision gears utilize modified tooth profiles (e.g., profile shifting and crowning) to distribute load evenly across the gear face, minimizing localized stress concentrations.

This robust construction ensures reliable performance in harsh environments, such as mining, oil and gas, and manufacturing.

3. Low Noise and Vibration Characteristics

Precision air compressor gears significantly reduce noise and vibration levels, a critical consideration in both industrial and commercial applications. Gear noise is largely caused by tooth impact and vibration during meshing. Precision manufacturing techniques address these issues through:

* Accurate Tooth Alignment: CNC machining and coordinate measuring machines (CMMs) ensure that gears are manufactured within precise tolerances, enabling proper alignment and minimizing axial runout.

* Surface Finishing: Polished tooth surfaces reduce contact friction and acoustic emissions.

* Helix Angle Optimization: In helical gears, carefully calculated helix angles balance thrust loads and noise generation, improving acoustical performance.

Reduced noise levels enhance user comfort and meet regulatory noise standards in workplace environments.

4. Extended Service Life and Reliability

Durability is paramount in air compressor applications, where downtime can result in significant production losses. Precision gears offer increased wear resistance and fatigue strength, leading to longer service life.

* Heat Treatment Processes: Induction hardening, carburizing, and quenching are applied to improve surface hardness and core toughness. This dual property balance prevents surface pitting and tooth breakage under repetitive loading.

* Lubrication Optimization: Precision gears are often paired with high-performance synthetic lubricants and integrated with optimized oil channels. This ensures consistent lubrication, lowering wear and thermal degradation.

* Corrosion Resistance: In applications where moisture and contaminants are present, gears may receive additional surface coatings (e.g., phosphate, PVD, or nickel plating) to prevent corrosion and extend usability.

As a result, precision gears contribute to low maintenance frequency, minimized downtime, and improved total cost of ownership.

5. Compact and Lightweight Design Possibility

Due to their high torque transmission efficiency, precision gears allow for downsizing of gearboxes and compressor assemblies. This is a crucial advantage in mobile, aerospace, or modular industrial compressor units.

* High Power Density: By transmitting more torque per unit volume, designers can achieve the same performance with smaller, lighter gear sets.

* Modular Gear Design: Precision gears can be integrated into compact modular gearboxes, facilitating easy maintenance, interchangeability, and scalability.

This reduction in size and weight is particularly beneficial in automotive air conditioning compressors, portable medical air systems, and aerospace cabin pressurization systems.

6. Increased Thermal Stability and Heat Dissipation

Air compressors generate substantial heat due to continuous mechanical work. Precision gears are designed with materials and surface treatments that enhance thermal performance.

* Thermally Stable Alloys: Precision gears are made from alloys with low thermal expansion coefficients, reducing gear deformation under high temperature conditions.

* Efficient Heat Dissipation: Tooth geometry and optimized surface area enhance convective and conductive heat dissipation. Additionally, precision alignment minimizes hotspots caused by uneven load distribution.

* Controlled Thermal Expansion: Advanced modeling (FEA and CFD simulations) during gear design anticipates thermal growth, ensuring operational consistency and preventing premature failure.

These features maintain gear integrity and operational reliability even during prolonged high-load operation cycles.

7. Customization and Integration Flexibility

Precision air compressor gears are highly customizable to suit application-specific requirements. This allows manufacturers to optimize the compressor system holistically.

* Customized Ratios and Configurations: Whether for single-stage or multi-stage compressors, precision gears can be designed with specific gear ratios to match desired pressure outputs and RPM ranges.

* Integration with Smart Systems: Gears can be outfitted with embedded sensors for temperature, torque, and vibration, enabling predictive maintenance and condition monitoring.

* Interfacing Capabilities: Designed to mate with specific shafts, bearings, and housing geometries, precision gears simplify system integration, reducing installation complexity.

This adaptability is valuable in industries with diverse compressor needs, such as semiconductor fabrication, pharmaceutical manufacturing, and food processing.

8. Energy Efficiency and Environmental Benefits

The superior performance characteristics of precision gears contribute to energy-efficient compressor operation, aligning with global sustainability goals.

* Lower Power Consumption: Reduced mechanical losses translate to lower input power requirements for the same compressed air output.

* Reduced Carbon Footprint: Higher system efficiency leads to reduced energy use, translating to lower greenhouse gas emissions over the compressor’s life cycle.

* Minimized Oil Consumption and Leakage: Precision sealing and lubrication systems result in cleaner operation and reduced environmental contamination.

As energy efficiency regulations tighten, especially in Europe and North America, precision gear integration becomes a key enabler of compliance and eco-friendly design.

Conclusion

Precision air compressor gears offer a wide array of application advantages, including enhanced efficiency, reduced noise, superior durability, and greater design flexibility. By integrating these high-performance components, air compressor systems achieve better energy performance, lower maintenance costs, and longer service lives, even under demanding industrial conditions.

The shift toward smart, compact, and energy-efficient air compressor solutions has made precision gears a critical design element. As manufacturing techniques and materials continue to advance, the role of precision gears in ensuring reliable, high-performance air compression will only become more pronounced. Whether in heavy industry or specialized medical equipment, investing in precision gear technology represents a tangible path toward operational excellence and sustainability.

www.lrfgears.com

Longruifa

Post Comment