Professional private label clothing manufacturer, helping brand development

In today's rapidly developing global fashion industry, branded apparel companies face increasing challenges: personalized and diversified consumer demand, efficient supply chain integration, and stringent requirements for sustainable development. In this environment, having a partner factory with the ability to manufacture their own brand, combined with technical expertise and fashion sensibility, has become crucial to a brand's success.

NEWSPRING, a professional private-label clothing manufacturer with 17 years of experience in producing garments for export, is the solid and powerful production support behind numerous international fashion brands. Adhering to the philosophy of "innovation-driven, quality-focused," we leverage advanced production equipment, professional manufacturing capabilities, and a global service focus to help major brands continuously expand their markets and lead fashion trends.

1. 17 Years of Experience, Builds Professional Manufacturing Capabilities

Since its establishment, NEWSPRING has focused on the manufacturing and export of garments for export, accumulating extensive industry experience. Our factory covers 8,000 square meters and employs over 500 highly skilled frontline employees. With an average monthly production capacity of 100,000 pieces and an annual output value exceeding 80 million yuan, we possess the ability to deliver efficiently and at scale. Having established long-term partnerships with clients in over 30 countries and regions, including Europe and the United States, NEWSPRING has earned widespread recognition globally through its stable product quality, efficient delivery system, and professional customer service, becoming a trusted partner of numerous renowned apparel brands.

2. Core Advantages of Private Label Manufacturers

Unlike traditional OEM (original equipment manufacturer) manufacturers, NEWSPRING possesses both original design (ODM) and original manufacturing (OBM) capabilities. This allows us to not only provide clients with finished product production services but also participate in the product design and brand development process. This truly integrates the entire "design-sample-production-quality control-delivery" process, saving clients time, controlling costs, and enhancing brand value.

2.1 Private Label Design Capabilities

NEWSPRING boasts a professional design team capable of providing creative design solutions tailored to international trends and client brand positioning. Whether it's streetwear, minimalist business, athleisure, or sustainable fashion, we precisely align with market demand, helping brands quickly launch new products and seize fashion opportunities. 2.2 Supporting Full-Process Customization

The company fully supports a variety of processes, including printing, embroidery, hot stamping, washing, thermal sublimation, and digital direct printing. We possess comprehensive automated process equipment, enabling us to meet diverse and personalized customization needs. Whether it's a small trial run or a large-scale production run of classic styles, we ensure stable production and on-time delivery.

3. Technology-Driven Production Automation and Informatization

As the apparel manufacturing industry moves towards intelligent manufacturing, NEWSPRING is actively introducing advanced production management systems and automated equipment to comprehensively improve production efficiency and quality control capabilities.

3.1 Automated Hanging Line System

The company has introduced an industry-leading automated hanging line system, digitizing traditional manual processes. This system enables automated connection and tracking of every step, from cutting and sewing to finishing. This system significantly improves production line efficiency, reduces labor waste, and enhances controllability and transparency throughout the entire production chain.

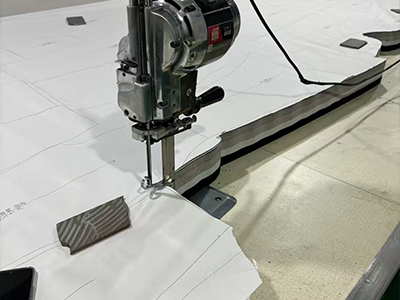

3.2 Computerized Automated Cutting System

By introducing a computer numerical control (CNC) cutting system, we ensure the cutting precision and fabric utilization of every garment. Automatic image recognition and layout, as well as precise cutting of multi-layer fabrics, not only shorten the sample cycle but also ensure standardization and consistency in mass production.

3.3 Intelligent Quality Control Process

NEWSPRING has a dedicated quality inspection department equipped with advanced testing equipment and SOP management processes. From fabric warehousing, through the production process, to garment delivery, we rigorously control quality throughout the entire process, ensuring that every product meets customer expectations.

4. Environmental Protection Integrated into Every Detail

Amidst the growing global trend toward sustainable development, environmental protection has become a key focus for apparel brands. NEWSPRING consistently adheres to green production principles, fully utilizing environmentally friendly materials and equipment to ensure that our products are not only aesthetically pleasing and comfortable, but also comply with environmental regulations.

4.1 Customized Eco-Friendly Fabric Services

We have established stable partnerships with several internationally renowned eco-friendly fabric suppliers and support the use of certified fabrics such as GOTS, OEKO-TEX, and GRS. We offer customers a variety of eco-friendly materials, including organic cotton, recycled polyester, and bamboo fiber, to meet brand sustainability strategies. 4.2 Green Equipment and Processes

NEWSPRING's printing and dyeing equipment and production processes all meet environmental standards, minimizing water and energy consumption and reducing the carbon footprint of production. We are also actively pursuing the goals of "zero wastewater discharge" and "low VOC emissions" to achieve a closed-loop green production management system.

5. Efficient Delivery and Service: Protecting the Brand

In today's fast-paced market, timely and high-quality product delivery is directly related to a brand's market performance. NEWSPRING understands this and has established a comprehensive project management and customer communication system to ensure that every batch of goods is delivered safely, quickly, and accurately.

5.1 Rapid Prototyping and Mass Production Capabilities

We have a comprehensive sample production and small-batch trial production process, enabling us to produce samples in as little as 48 hours and deliver small batches within 7 days. Furthermore, with our robust production capacity and manpower allocation system, we can quickly organize large-scale production upon order confirmation, ensuring stable delivery schedules. 5.2 International Logistics Collaboration System

We have established in-depth partnerships with several renowned international logistics companies, supporting various modes of transportation, including air, sea, and express delivery. Our dedicated international customer service department ensures real-time communication and rapid response, ensuring every customer enjoys a professional, efficient, and transparent service experience throughout the entire purchasing process.

6. Win-Win Cooperation: Growing Together with Global Brands

Currently, NEWSPRING has established stable partnerships with clients in over 30 countries worldwide, covering a wide range of categories including men's, women's, children's, sportswear, homewear, and functional apparel. Our clients include major e-commerce platform brands, offline fast fashion chains, and independent designer brands.

We uphold the core value of "joint growth and win-win cooperation." Through technology input, resource integration, and flexible manufacturing capabilities, we provide clients with one-stop solutions to support brand upgrading and global expansion.

Looking ahead, NEWSPRING will continue to deepen its presence in the apparel manufacturing sector, expanding its service offerings and product capabilities to include more forward-looking offerings. We will further increase investment in technological innovation, exploring areas such as digital pattern making, flexible supply chain collaboration, and AI-powered cutting, to continuously enhance our core competitiveness.

At the same time, we will focus on deepening our collaboration with brands. Through big data analysis, fashion trend research, and flexible manufacturing models, we will provide customized, sustainable, and efficient full-chain support, truly achieving the goal of "empowering brands with manufacturing and leading fashion with service."

As a professional private label apparel manufacturer, NEWSPRING is not only an efficient clothing production facility but also a solid innovation force behind numerous brands. Leveraging 17 years of expertise, we provide one-stop fashion solutions for customers around the world.

Moving forward, NEWSPRING will continue to uphold its original aspiration of "innovation leads fashion, service builds brands," partnering with more high-quality brands to forge a new chapter in the fashion industry. For custom private label apparel, please contact NEWSPRING. We will build a unique dual engine of "productivity" and "fashion power" for your brand!

www.ncnewspring.com

ncnewspring

Post Comment