Cement grouting in structural backfilling: why it is superior to traditional materials

https://www.shanyijc.com/Cement-grouting-in-structural-backfilling.html

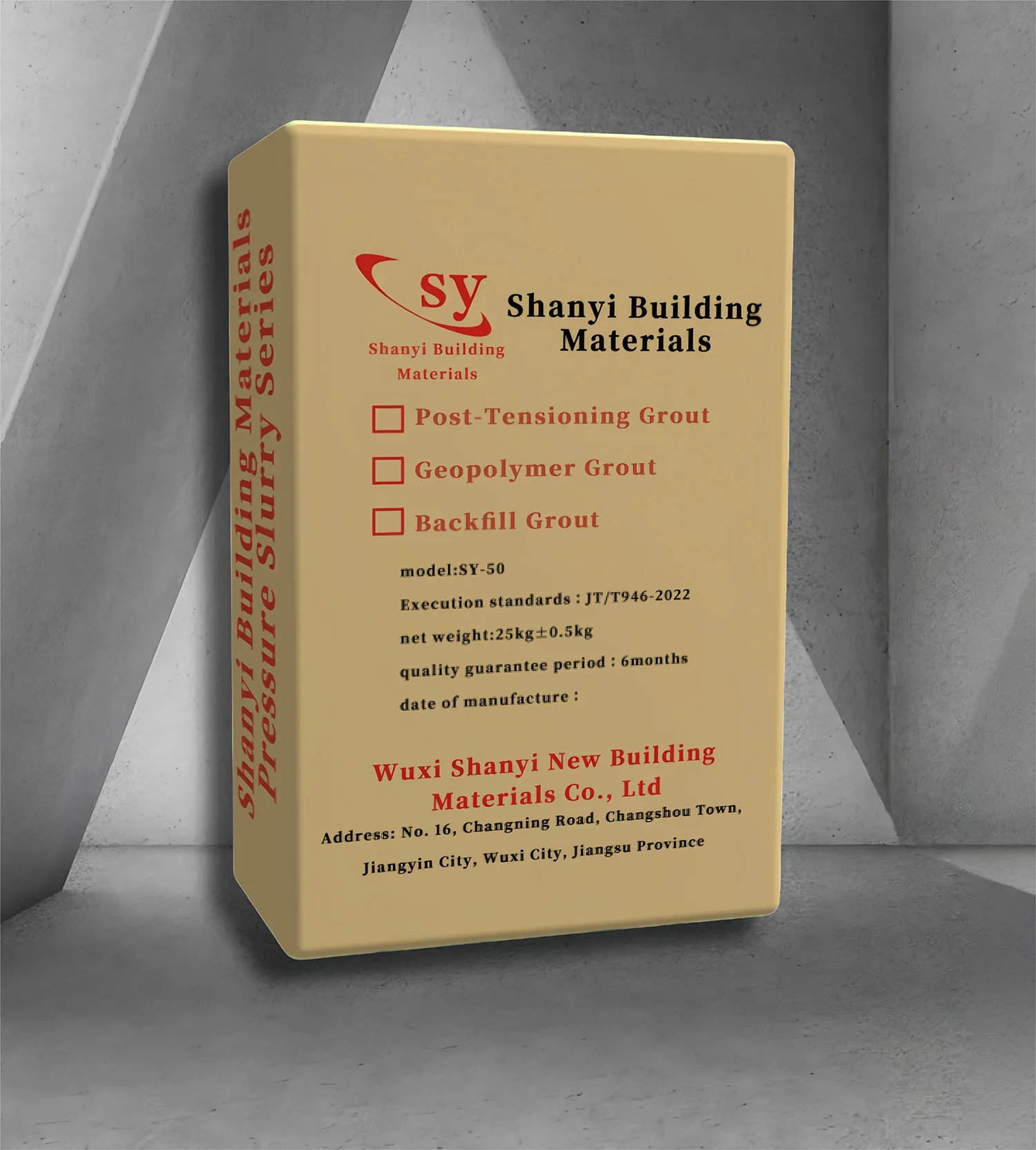

In today’s construction industry, the demand for materials that combine strength, efficiency, and long-term durability is higher than ever. Traditional mortar and ordinary cement grouts have long been used for backfilling and structural reinforcement, but their limitations in strength, flowability, and shrinkage resistance can compromise performance in demanding projects. Structural backfill cement grout offers a modern solution, providing superior mechanical and durability characteristics. Wuxi Shanyi New Building Materials Co., Ltd. specializes in high-performance cement grouting materials that meet the stringent requirements of advanced engineering applications.

Advantages Over Ordinary Mortar and Cement Grout

-

Higher Strength

-

Structural backfill cement grout is engineered to achieve higher compressive and bonding strength than traditional mortar.

-

This ensures stability and load-bearing capacity in critical applications such as bridge supports, machine foundations, and underground structures.

Enhanced Flowability

-

Unlike ordinary mortar, which may be difficult to place in tight or complex spaces, structural grout maintains excellent fluidity.

-

This property allows it to penetrate voids and gaps efficiently, ensuring full compaction and eliminating weak zones.

Low Shrinkage

-

Shrinkage is one of the primary causes of cracks and voids in cement-based materials.

-

Structural grout incorporates additives that minimize shrinkage, preserving the integrity of the structure and preventing long-term settlement issues.

Outstanding Durability

-

With superior resistance to chemical attack, freeze-thaw cycles, and mechanical wear, structural grout ensures a longer service life compared to conventional materials.

-

Its durability makes it ideal for infrastructure exposed to harsh environments, such as tunnels, marine structures, and heavy-duty industrial foundations.

Performance Features in Modern Applications

-

Precision Backfilling: Guarantees complete contact between structural elements, enhancing load transfer efficiency.

-

Versatile Usage: Suitable for bridges, highways, high-rise buildings, and energy projects.

-

Sustainability: Advanced formulations reduce material waste, extend service life, and support sustainable construction practices.

-

Reliability: Provides consistent performance under both static and dynamic loads.

Wuxi Shanyi New Building Materials Co., Ltd. Solutions

As a trusted manufacturer, Wuxi Shanyi New Building Materials Co., Ltd. delivers structural backfill cement grouts that combine cutting-edge formulations with proven reliability. Their products are specifically designed to outperform ordinary mortar and traditional grout, ensuring:

-

High compressive and flexural strength.

-

Excellent flow characteristics for easy placement.

-

Reduced shrinkage and cracking.

-

Long-term resistance to environmental and mechanical stresses.

By choosing Wuxi Shanyi’s cement grout solutions, contractors and engineers can achieve safer, more durable, and more efficient construction results.

Structural backfill cement grout represents a significant advancement over conventional mortar and ordinary cement grout. With its high strength, superior flowability, low shrinkage, and exceptional durability, it addresses the limitations of traditional materials while meeting the challenges of modern construction. Wuxi Shanyi New Building Materials Co., Ltd. continues to lead the industry by providing innovative grouting solutions that enhance structural performance and ensure long-lasting reliability in critical engineering projects.

https://www.shanyijc.com/Cement-grouting-in-structural-backfilling.html

Wuxi Shanyi New Building Materials Co., Ltd.

Post Comment