Application of Double Planetary Mixers in Adhesive and Sealant Manufacturing with a Hydraulic Extruder Filter at the Outlet

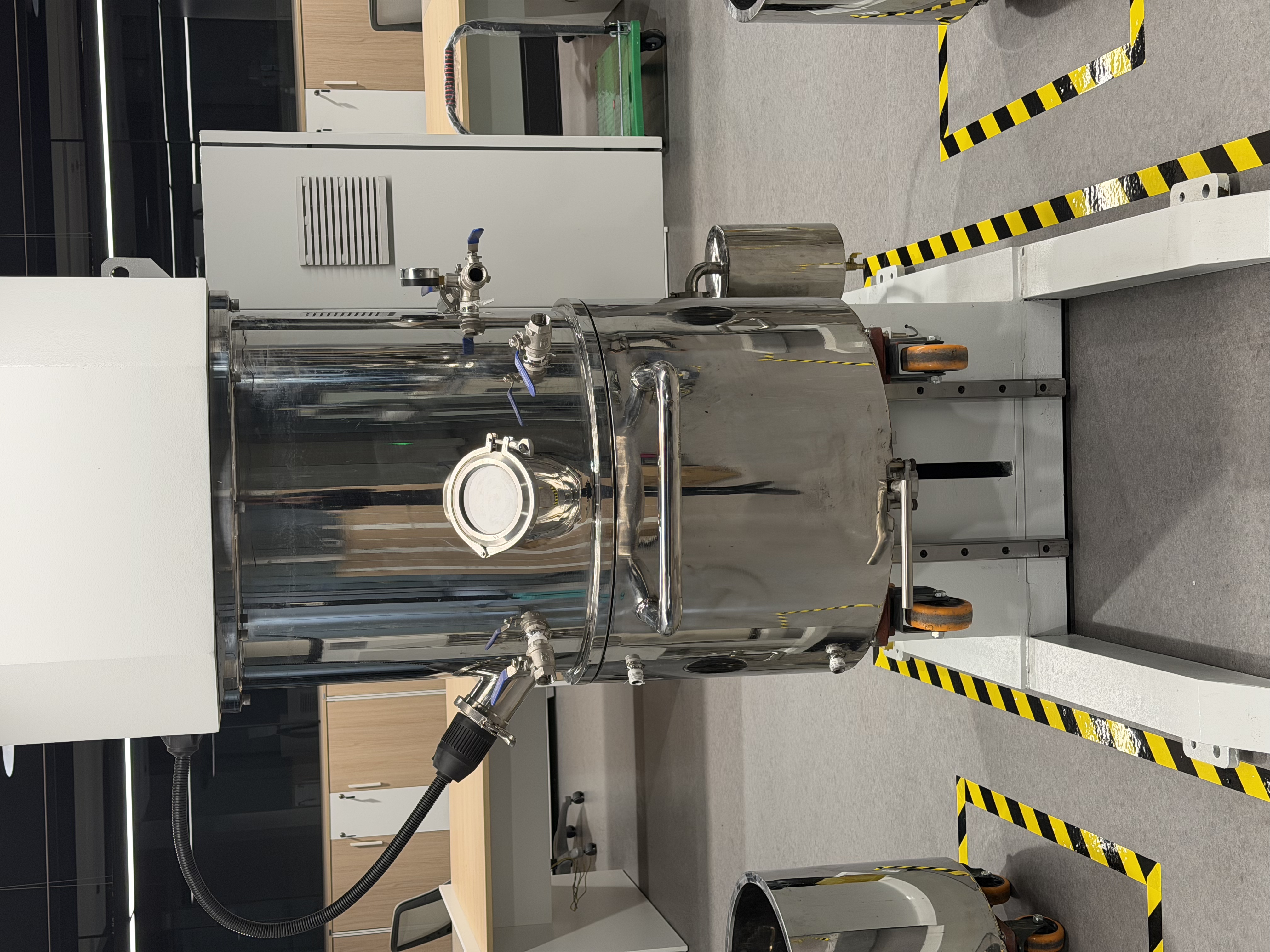

The adhesive and sealant industry demands equipment capable of handling high-viscosity, high-precision, and high-consistency formulations. Among the most reliable technologies in this field, the Double Planetary Mixer has become a preferred solution for producing structural adhesives, silicone sealants, MS polymers, battery pastes, epoxy systems, and more. When paired with a hydraulic extruder filter at the outlet, its efficiency, product quality, and processing stability are significantly enhanced.

As a professional machinery manufacturer, Orisun, known for its advanced mixing technologies and precision-engineered production systems, provides robust, high-performance, and high-reliability double planetary mixers designed for demanding industrial applications.

Understanding the Role of Double Planetary Mixers in Adhesive and Sealant Production

A double planetary mixer is engineered for materials with extremely high viscosity and complex rheological behavior. In adhesive and sealant production, formulations often reach hundreds of thousands to millions of centipoise, making traditional mixing methods ineffective.

The double planetary mixer features two individual agitators that rotate on their own axes while orbiting the mixing bowl. This creates a powerful, efficient, and uniform mixing motion ideal for handling dense materials.

Manufacturers like Orisun design these mixers with precise gear mechanisms, heavy-duty construction, and optimized rotor geometry, ensuring consistent blending for both small-batch specialty sealants and large-scale adhesive formulations.

Advantages of Double Planetary Mixers for High-Viscosity Formulations

Double planetary mixers offer several strong product advantages, making them essential for professional adhesive and sealant processing:

-

Superior mixing homogeneity

The planetary motion ensures thorough material turnover and complete integration of powders, polymers, fillers, and additives. -

High-viscosity handling capability

The mixer can process materials that exceed the limits of conventional agitators, maintaining stable torque and mixing efficiency. -

Low-shear but high-efficiency mixing

This prevents overheating, molecular breakdown, or deformation of sensitive ingredients. -

Customizable mixing tools

Choices include rectangular blades, finger blades, and special hybrid tools for different material behaviors. -

Vacuum-compatible design

Enables deaeration, removal of microbubbles, improved clarity, and enhanced mechanical strength.

Orisun’s double planetary mixers feature precision-engineered components, durable stainless-steel construction, and smart control systems, ensuring repeatable performance for demanding industrial workflows.

Importance of a Hydraulic Extruder Filter at the Outlet

In adhesive and sealant manufacturing, transferring high-viscosity material out of the mixing tank is often a challenge. A hydraulic discharge system with a filtration unit solves this efficiently.

The filtration system performs several critical functions:

-

Removes impurities or solid contaminants

Ensures the final product is clean, smooth, and meets quality standards. -

Improves product consistency and appearance

Essential for applications where surface finish and homogeneity matter. -

Enables efficient and clean discharge

Prevents material loss and reduces downtime during batch transitions. -

Enhances safety and operational efficiency

Minimizes manual handling of viscous materials.

When paired with Orisun’s high-pressure hydraulic extruders, the entire discharge workflow becomes streamlined, allowing users to maintain stable, clean, and high-efficiency production.

Practical Applications in Industrial Manufacturing

Double planetary mixers with hydraulic extrusion are widely used in producing:

-

Epoxy adhesives and structural bonding systems

-

RTV and HTV silicone sealants

-

PU and MS polymer sealants

-

Acrylic and epoxy flooring compounds

-

Thermal interface materials and battery pastes

-

Ceramic slurries, putties, and dense industrial coatings

Orisun’s solutions are engineered to handle all these applications with professional-level precision, industrial durability, and long-term reliability.

Why Orisun Is a Trusted Partner for Advanced Mixing Solutions

As a specialized equipment manufacturer, Orisun offers complete adhesive and sealant production solutions that combine mechanical innovation with practical industry experience. Their equipment is known for:

-

Strong structural design for long service life

-

High-precision mixing performance for demanding formulas

-

Customizable configurations for different industries

-

Reliable vacuum, heating, and cooling options

-

Stable control systems for repeatable results

-

Full technical support from installation to operation

This makes Orisun an excellent choice for companies seeking efficient, high-quality, and production-oriented mixing systems.

Conclusion

The integration of a double planetary mixer with a hydraulic extruder filter represents a powerful solution for adhesive and sealant manufacturing, ensuring excellent mixing performance, clean discharge, and stable product quality. With advanced engineering and industry-tested designs, Orisun continues to deliver equipment that helps manufacturers achieve higher productivity, greater consistency, and superior results in every batch.

Applications of Planetary Mixer–Extruder Systems in Chemical, Pharmaceutical, and Battery Materials

www.orisunmachinery.com

Orisun

Post Comment